Efficient granulation

Pelletizing

We offer professional pelletizing systems for the plastics industry. In addition to strand pelletizing systems (normal and underwater), we also have melt pumps, dryers and powder mills in this product category.

Maag

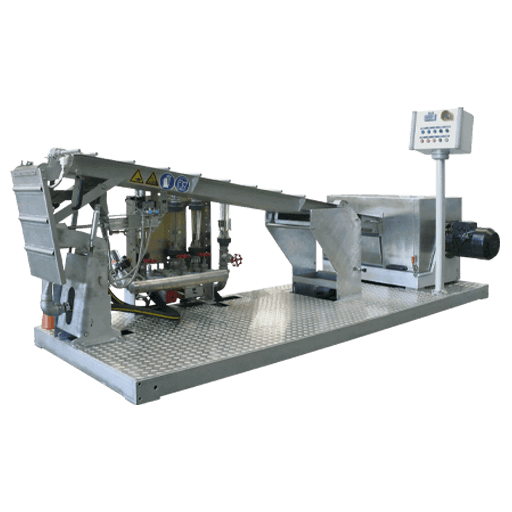

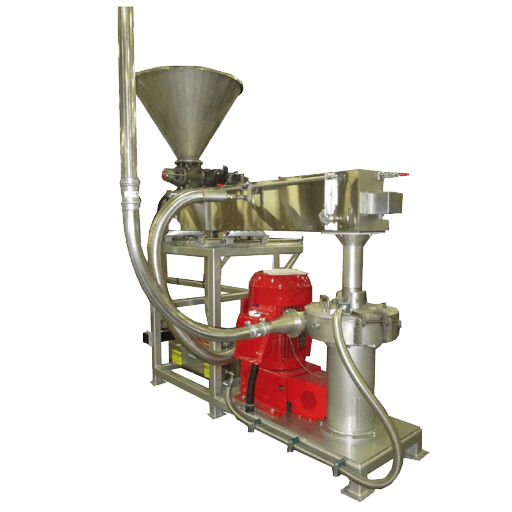

Strand pelletizing systems

From small laboratory granulators type SGS 25-E4, to the BAOLI series for simple applications, to the Primo series with the largest number of equipment options, the EBG series for water-sensitive or highly filled materials, there is the optimum granulator for every application.

Applications range from compounding, masterbatch, recycling, rotomolding to polymer production.

Technical data

Throughput

max. 12500 kg/h

Granule size

0.5 - 10 mm

Maag

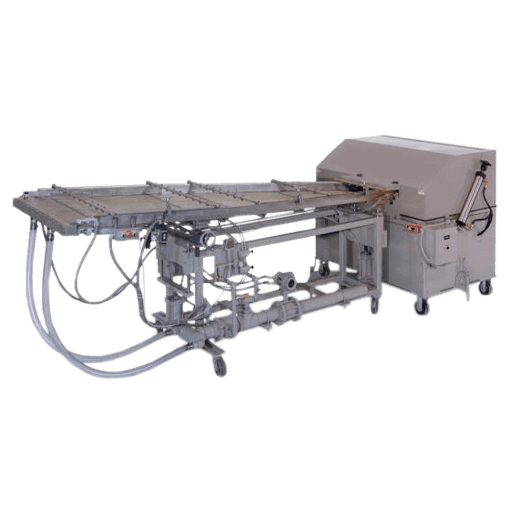

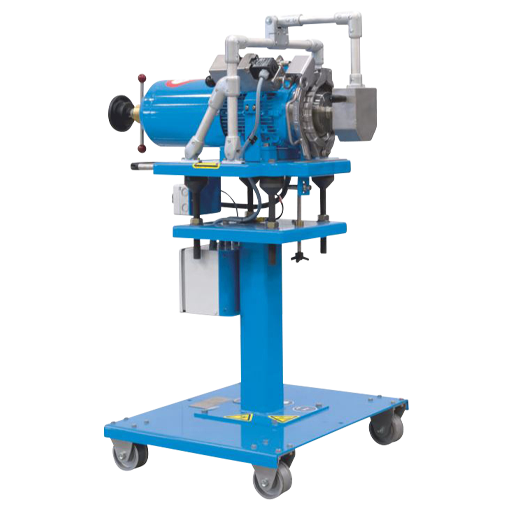

Underwater strand pelletizing systems

From small laboratory granulators type SGS 25-E4, to the BAOLI series for simple applications, to the Primo series with the largest number of equipment options, the EBG series for water-sensitive or highly filled materials, there is the optimum granulator for every application.

Applications range from compounding, masterbatch, recycling, rotomolding to polymer production.

Technical data

Throughput

max. 20000 kg/h

Engine power

250 m/min

Maag

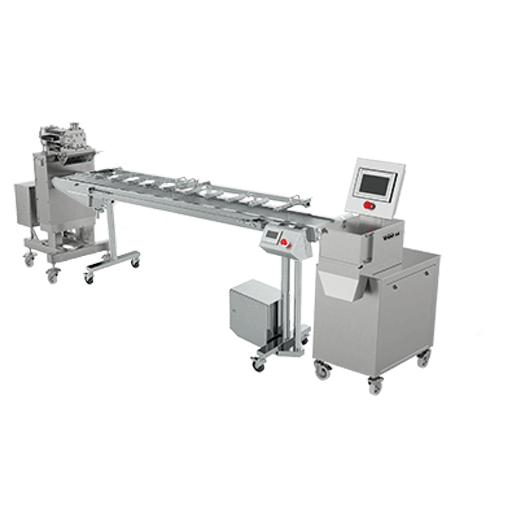

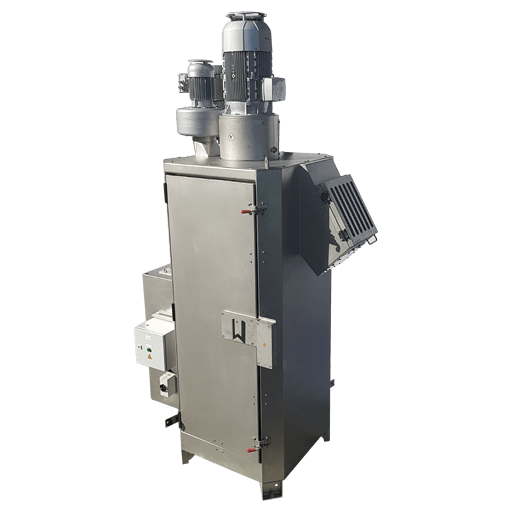

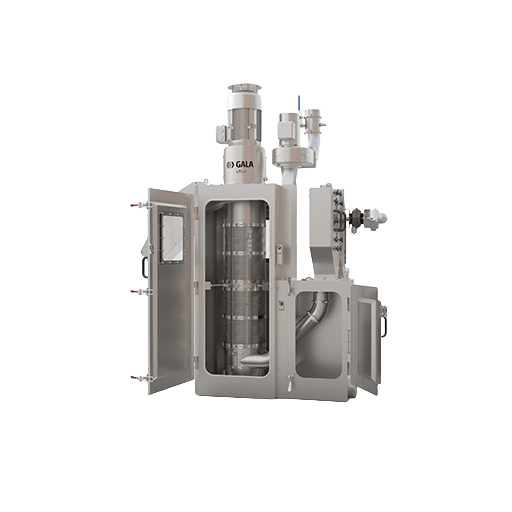

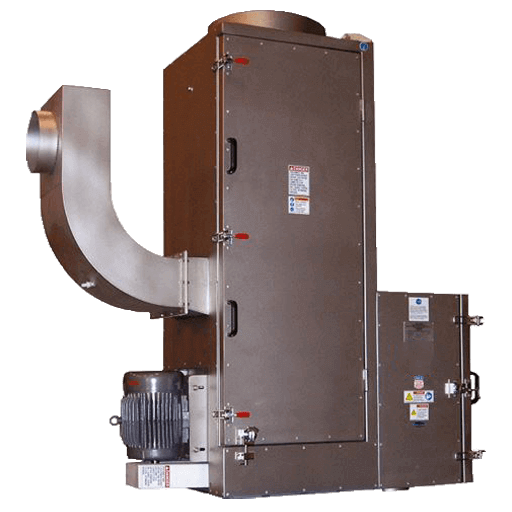

Dryer

For the drying of polymer pellets, MAAG offers various high-end dryers that are excellently matched precisely to the strand pelletizing and underwater pelletizing systems.

The various centrifugal dryers including CYCLO, eXso dryer, ECLN, EA or Model SC are excellent for centrifugal drying of granules. The centrifugal dryers are very easy to maintain and operate.

DURO belt dryers are particularly recommended when sensitive granules (e.g. glass fiber) or brittle or abrasive materials are used.

The AERO impact dryers operate without mechanical moving parts and separate the granules from the water. The mode of operation is very granule friendly and excellent for delicate materials.

Applications range from compounding, masterbatch, recycling, rotomolding to polymer production.

Technical data

Throughput

max. 40000 kg/h

Air performance

max. 125m³/h

Water flow rate

max. 250m³7h

Maag

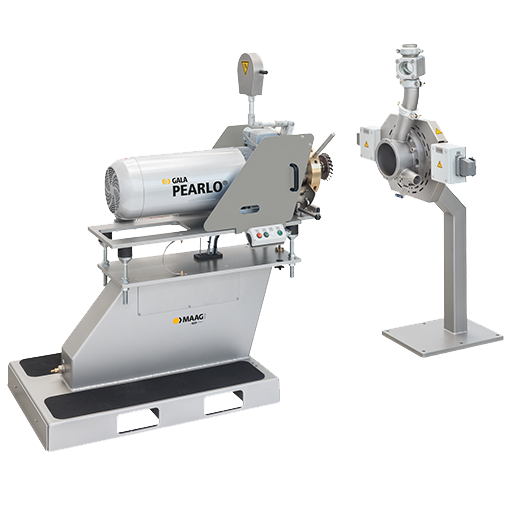

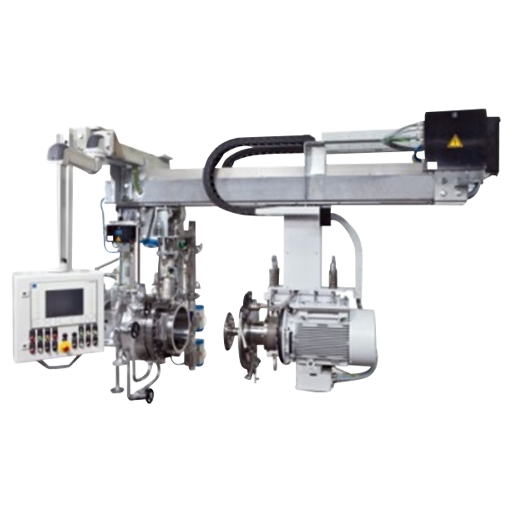

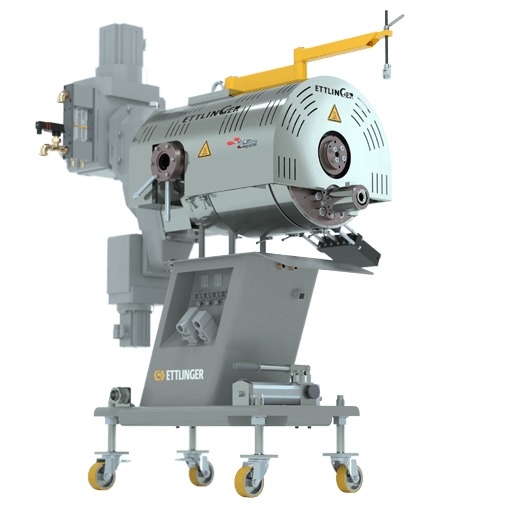

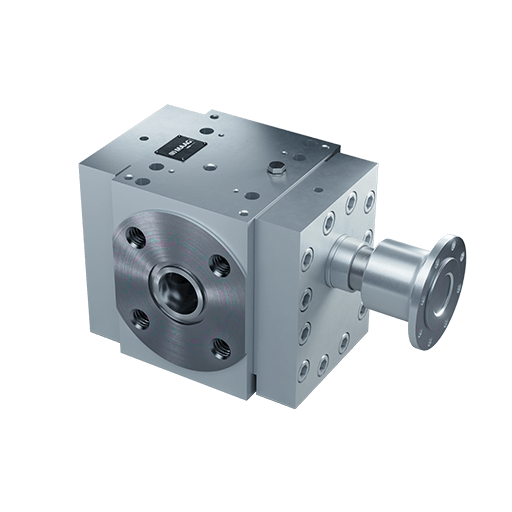

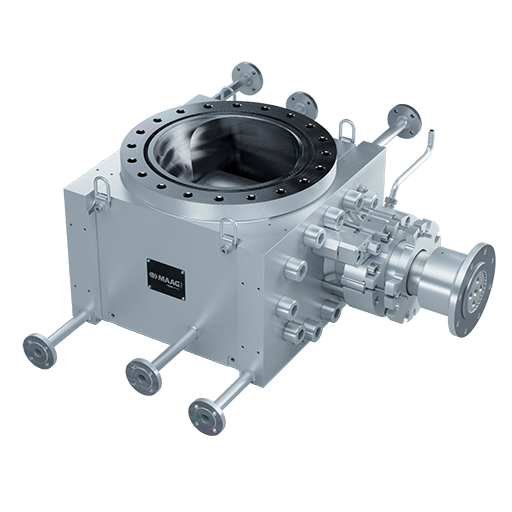

Melt filter Melt pumps

Melt filters and melt pumps complete the MAAG delivery program and thus offer the complete periphery from one source. The melt pumps and filters can be integrated into existing production systems.

The melt filters are suitable for impurities up to 16%. This can be used to remove a wide range of polymers, aluminum, wood, silicones, copper, paper and more.

MAAG melt pumps work very efficiently, have a long service life and are easy to maintain. They are mainly used in polymer production and are particularly suitable for discharge from reactors, for pressure build-up before pelletizing or for stable melt discharge.

Technical data

Throughput

0.4 - 265 l/min

Speed

1500 rpm

Temperature

30 to 350 °C

Maag

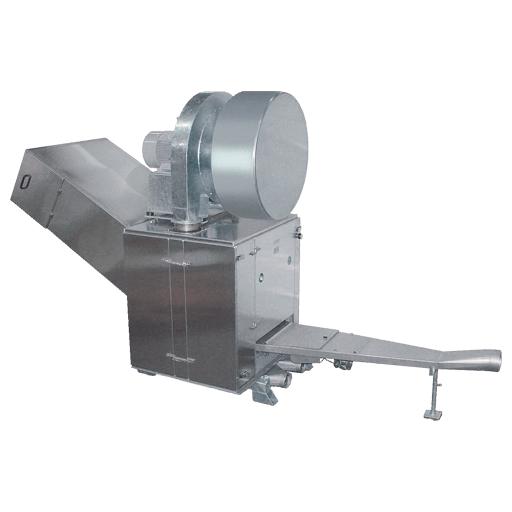

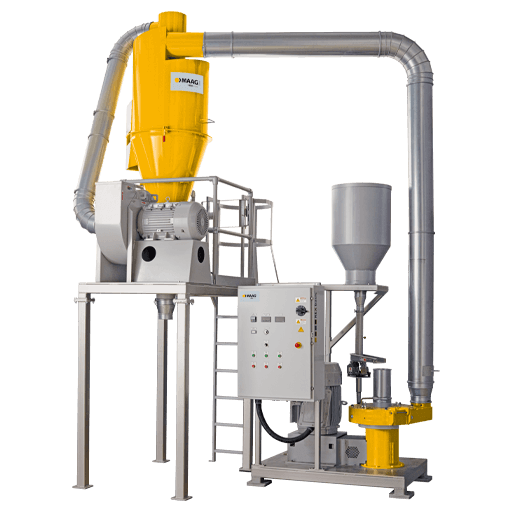

Powder mills

For the areas of recycling, compounding and rotomolding, there are different types of powder mills, both for the laboratory area and for production. These are characterized by their compact design and their wide range of applications.

Technical data

Throughput

1-1360 kg/h

Engine power

max. 55 kW

Disc diameter

2/457 mm

We are here for you

Get in contact with us

Do you still have questions about our material handling solutions? Feel free to contact our sales staff directly or send an e-mail to office@sipa.at.